1. Efficient Production: The use of automated operations and a fast lamination speed greatly enhances production efficiency, saving time and labor costs.

2. Strong Stability: By utilizing high-quality materials and advanced technology, the machine ensures stability and reliability, minimizing the occurrence of malfunctions during long-term operation.

3. Easy Operation: The control method of PLC+HMI interface simplifies operation and reduces training costs for operators.

4. Versatility: This laminating machine is suitable for various types of film materials and finds wide applications in industries such as packaging, printing, and advertising.

We firmly believe that the automatic laminating machine (double pressure) will be the optimal choice for your lamination process. Whether it is to enhance product quality or improve production efficiency, it will bring significant benefits to you.

Dry Film Auto Cutting Laminator

Electronic products: Panels, circuit boards and other components of electronic products often need to go through a film process to fix components or protective layers to ensure product quality and durability.

Shipping package:Standard Package, Wooden Package, Vacuum Package (Standard package, wooden package, vacuum package).

Port: Shenzhen Port Guangzhou Port.

Payment method: LC, T/T.

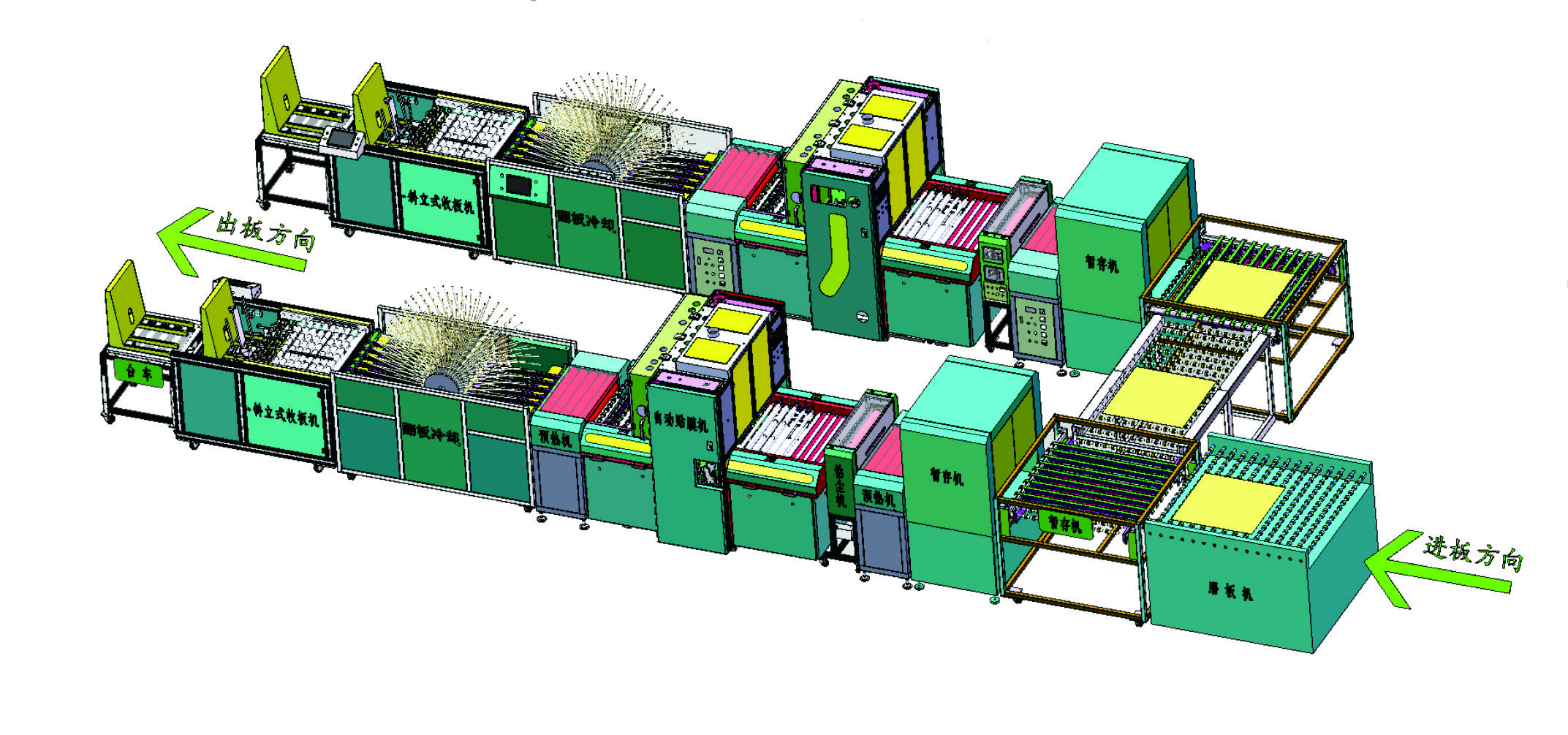

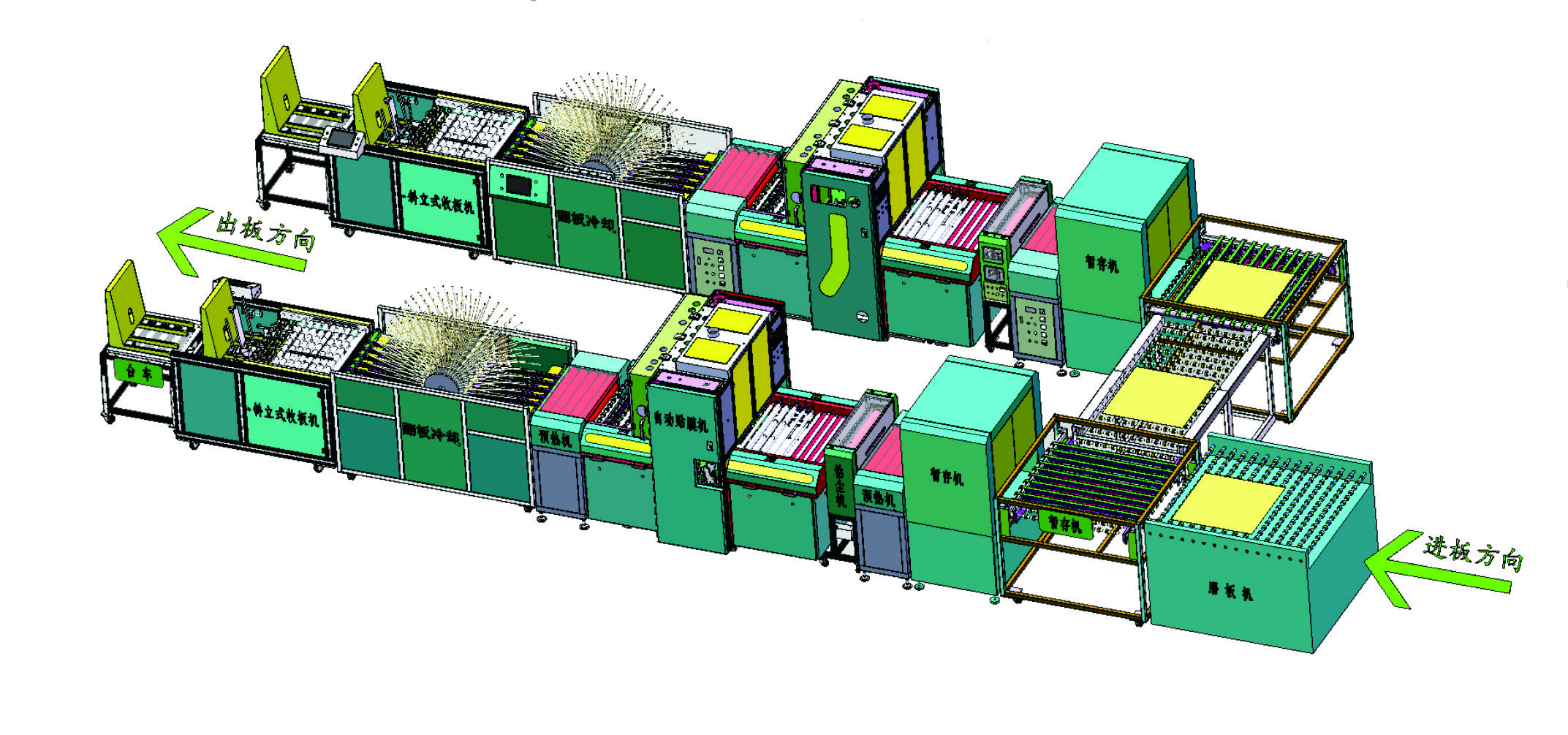

Process flow chart display

Product Parameter

model number: GH-A640

current source :AC380V 3 Phase 15KW 50HZ

pressure :5-8kgw/c㎡

:5-8kgw/c㎡

outline dimension:L2200*W1540*H1910mm

The effective width of the film pressure:650MM

Baseline length: 250~660mm

Baseline width: 250~660mm

Baseline thickness: 0.1~3.3mm

Dry film size:

Membrane width:250~650mm

film thickness:15~76μm

Membrane diameter:external diameter 200mm

control method:PLC+human-computer interface

Hot pressure:Ø 78mm*760mm

Heating method:Inductive heater

Number of hot pressing rollers:4

Pressure membrane speed:velocity range 0~5.5m/minMan-machine interface is set arbitrarily。

Film pressure temperature:SSR+PLC temperature control room temperature ~130℃

Main material:SUS304Mirror stainless steel。

Pressure membrane pressure:2-6kg/cm2(adjustable)

vacuum grip device:Five-section operation width setting

Vacuum pump:2.2KW(3HP)

Vacuum suction disc range:9 "~13 ",14 "~17",18"~21",22 "~25 "

Silicone wheel Ø 40m/m,Stainless steel roller Ø 31.5mm P=74mm

structure:Host body mobile type, convenient for dry film replacement

Before dew copper:0.0~49.9mm

After dew copper:0.0~12.9mm

Brass error:±1.0mm

Board edge error:±1.0mm

exhaust:40CM(caliber Ø 4")

weight of equipment: About 1,360 kg

:5-8kgw/c㎡

:5-8kgw/c㎡